This two-volume new addition to our collection of works on engineering and industrial production marks an important milestone in the publishing history of the Industrial Revolution.

The author, Carl Hartmann (1796-1863), was one of the most respected and acclaimed mineralogists and metallurgists of his time. The son of a steelworks official from Brunswick, he trained first as a mining engineer, then studied mineralogy at the University of Berlin, before reading for the law in Heidelberg. By 1825, he was already publishing on metallurgy and it was partly one the strength of his reputation from these publications that in 1829 he became the Commissioner of Mines for the Duchy of Brunswick. Hartmann’s texts became must-reads and were to be found on the shelves of fellow specialists. Among these were GF founder Johann Conrad Fischer (1783-1854), who is known to have had at least two of Hartmann’s treatises of iron and steel production in his library.

Apart from being a gifted mining engineer, Hartmann was also a talented linguist, and this gave him access to the latest technical writings from England and France. By the end of his career, he had authored 28 books and translated a further 18.

The Industrial Revolution’s rising tide technological modernisation had swept away many traditional ways of life and indelibly changed cultures of manufacture and business. As machines replaced traditional crafts, increased production and expanded potential, specialisms began to develop within industries and their champions plunged headlong into the detailed expansion of their fields. It was an environment of technical terms, components and concepts that soon became difficult for economic administrators, bankers, investors, or the inheritors of industrial complexes and would-be industrialists to navigate.

This is where Carl Hartmann’s 1838 Encyclopaedic Handbook came into play. The two volumes served as a foundational text, offering a comprehensive overview of the burgeoning fields of machine engineering and factory management, while concisely giving vital insights into the latest technological advancements, manufacturing processes, and organizational methods.

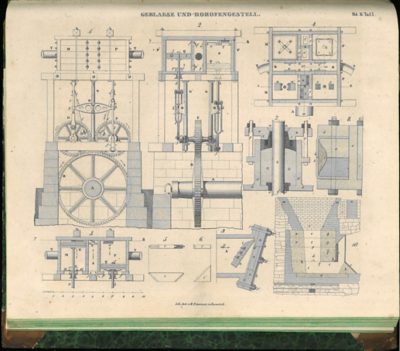

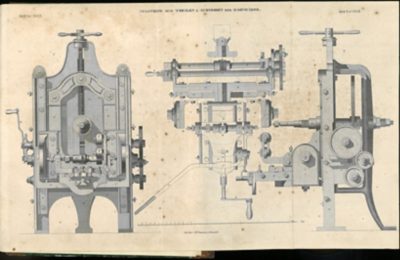

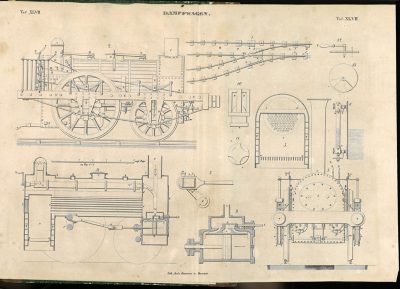

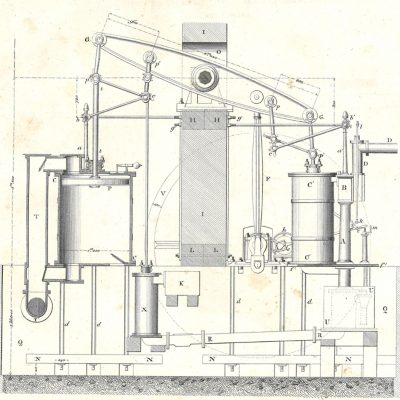

Included among the principles of running a factory, for instance, is an explanation of the necessity of the division of labour. Materials sciences for the operation of machinery are dealt with pragmatically. For example, the quantities of grease required for reducing friction between the contacting surface of components made of different types of metal and wood are given ample focus, as this is where the most frequent breakdowns occurred, causing the most work stoppages or even fires. The two volumes are fully illustrated, too, with highly detailed technical drawings of cranes, water wheels, water lifting mechanisms, pumps, steam engines, printing presses, sawing mills, paper machines, mills, train lines and the locomotives that ran on them, as well as arrays of metallurgical equipment like blast furnaces and coin presses.

By compiling his wealth of knowledge, Carl Hartmann facilitated the dissemination of crucial information. Now as then, his encyclopaedic handbook offers a fascinating insight into the latest technological advancements, manufacturing processes, and organizational methods of his time. 186 years later it is still every inch the crash course that it was, albeit for historians of the Industrial Revolution!